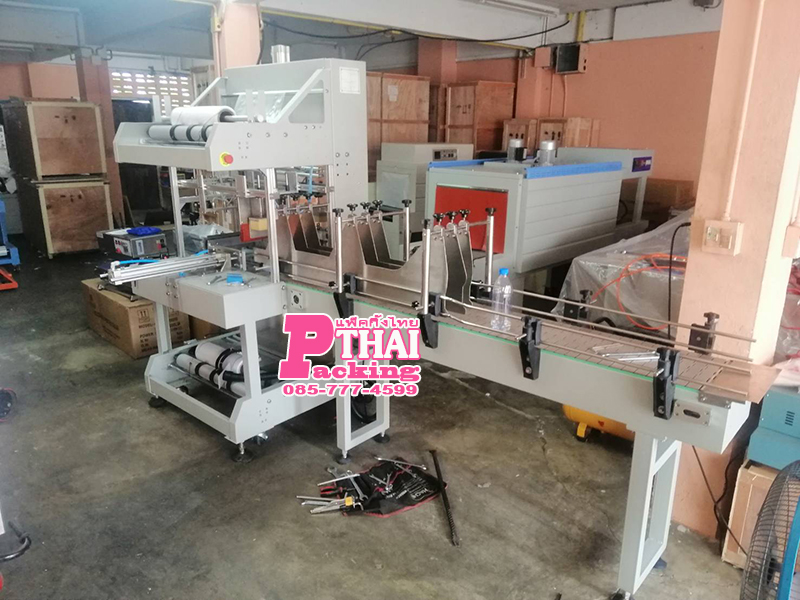

เครื่องห่อแพ็คโหลอัตโนมัติ รุ่น BSF-6030XI

เครื่องห่อแพ็คโหลอัตโนมัติ สำหรับห่อแพ็คโหลขวดน้ำดื่ม ใช้กับขวดน้ำดื่มได้หลากหลายขนาด

Description

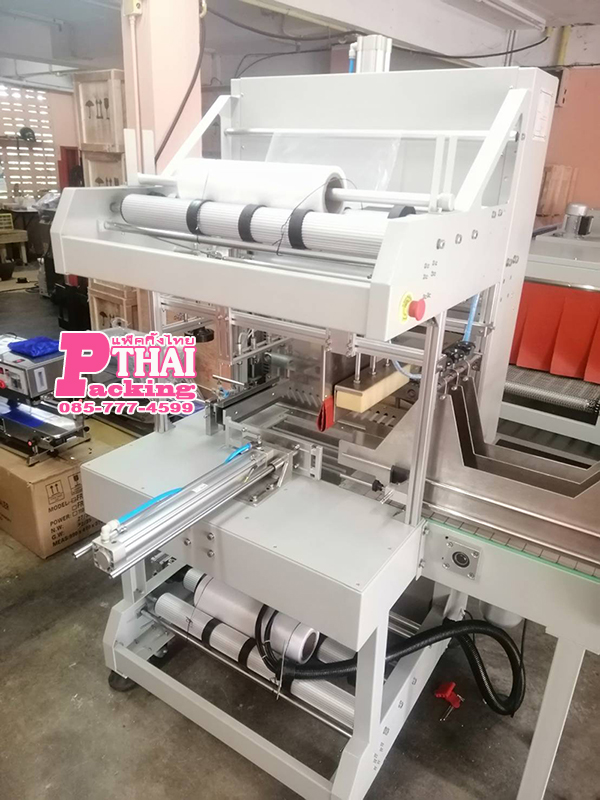

BSF-6030XI automatic sleeve film sealing and cutting machine is imported from foreign advanced technology and process, and the equipment performance is stable and reliable.

- Mitsubishi PLC programmable program controller is used to realize integration of light, machine, electricity and gas.

- The feeding conveyor can be designed to feed on the left or the right according to the needs of the site.

- Specially designed sealing knife, the sealing line is firm, not cracking, and not easy to stick to the knife; LFPOM material conveyor belt is resistant to wear and high strength.

- The machine can be used for two-, three-, and four-row heat shrinkable packaging with or without a bottom bracket. According to the production requirements, only the changeover switch on the panel needs to be changed.

- The worm gear reducer is used to ensure smooth and jitter-free feeding and film feeding.

- Vibration feeding device can be selected according to bottle shape.

- When packaging color film, add a full set of photoelectric detection to accurately position.

- Modular design, changing different bottle shapes can be completed instantly.

| BSF-6030XI | |

| Power supply voltage (V / Hz) | 380/50 (3PH) 220/60 (3PH) |

| Use of air source (kg / cm³) | 6-8 |

| Power (KW) | 2 |

| Packing speed (PCS / H) | 0-12 |

| Maximum packing size (L × W × H) (mm) | 450 × 300 × 300 |

| Sealing and cutting size (L × H) (mm) | 700 × 330 |

| Admission work horizontal height (mm) | 880 ± 30 |

| Applicable film | PVC, PE |

| Dimensions (L × W × H) (mm) | 1360 × 2120 × 1900 |

| Net weight (kg) | 465 |